Making Headlines

When you make outstanding products, you make news.

Two-shot plastic overmolding has become a vital technology in the world of plastic injection molding, bringing unique advantages and possibilities to the medical device industry. In this article, we highlight AVNA’s advantage in delivering plastic molding solutions for medical device components and assemblies.

Ready to Learn More? Contact Us NowTwo-shot molding combines two different thermoplastics into a single molded component, creating intricate, multi-color, multi-material components, reducing the number of components in a finished assembly.

Two-shot molding is used for medical devices that require:

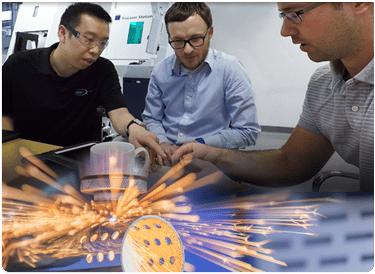

AVNA‘s two-shot molding technology combined with advanced laser technologies and secondary forming of metal tubing provides a vertically integrated solution for medical device solutions such as trocars used in laparoscopic procedures.

AVNA offers major global MedTech OEMs the unique vertical integration of single and two-shot overmolding capabilities with advanced contract manufacturing of high-precision, complex metal device components all under one roof. The result is a streamlined manufacturing process that not only optimizes efficiencies and cost savings, but exceeds quality, functionality, and reliability expectations.

With years of engineering and manufacturing experience in advanced laser technologies, intricate metal tube cutting and forming, CNC machining, stamping, and now plastic single and multi-shot overmolding, AVNA offers custom manufacturing solutions MedTech OEMs require.

In-house custom automation, tool and machine building, manual/automated integrated visual quality systems, and robust secondary operations, provide adept, nimble solutions for producing highly complex plastic-on-metal solutions that are stronger and more reliable.

Ready to Learn More? Contact Us NowAt AVNA’s Costa Rica facility, two-shot molding technology is combined with advanced laser technologies and secondary forming of metal tubing to provide a vertically integrated solution for trocars used in laparoscopic procedures.

The process begins with bar feeding 10ft stainless steel tubing into our laser tube cutting system. Integrated forming tools within the cutter simultaneously form specific features on the distal and proximal ends of the tube for overmold retention. The parts are then fed back into the machine for a custom forming process that reduces the diameter of the distal end of the tube. The precision cut and formed tubes are then passivated in-house and proceed to our two-shot molding machines with in-house tool and automation design. With custom-built automation, finished tubes are loaded on the core pins where two different resins are simultaneously injected on the distal and proximal ends of the tube. Plastic material adheres firmly to the tube, creating seamless bonds that withstand mechanical stress and temperatures. The result is a highly efficient manufacturing process providing superior product quality and performance.

AVNA’s NexTech Labs allows customers the ability to collaborate with our engineers in the early phases of product development to develop and test prototypes and ultimately design a custom process that optimizes manufacturability, speed to market, and product performance.

The Company’s commitment to innovation doesn’t stop here. The team continually seeks ways to further improve processes and invest in the latest technologies to optimize cost savings as an added benefit to our customers.

With three locations in New Britain and Berlin, CT and Alajuela Costa Rica, AVNA is more than just a manufacturing company. It’s a team of collaborative problem-solvers, committed to pushing the boundaries of what’s possible. If you’re looking for a partner to bring your complex, multi-material products to life, AVNA’s team is ready to help. Fill out the contact form below to get in touch with us today.