Making Headlines

When you make outstanding products, you make news.

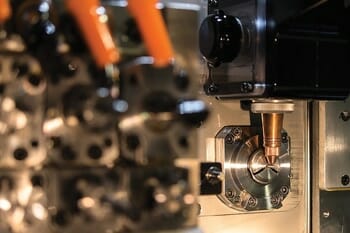

A concentrated beam of light. Advanced machining capabilities. LaserSwiss has both, delivering efficiency and lowering costs by combining the precision of Swiss turning with a fully-integrated laser cutting system. While the low cycle times of laser processing provide precision accuracy and high-yield production, machining processes are sometimes required, due to part design, or to maximize manufacturability.

For some manufacturers, this may mean moving a laser-cut part onto a new piece of equipment, increasing part handling, quality processes and production time. Machining processes typically have higher cycle times, which only increases with movement from machine-to-machine. Combining two proven manufacturing methods into a single pass operation means output, quality and repeatability can be improved. Here are some tips on how OEM’s can utilize LaserSwiss manufacturing processes to solve complex engineering challenges.

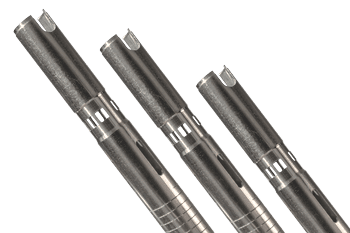

Tube diameters from 2.0mm (.080”) to 12.7mm (½”), wall thicknesses down to .05mm (.002”) and laser cut widths as small as 0.05mm, can be manufactured with LaserSwiss. Now components that require intricacy, tight geometries, fine or angular cuts, or a high-degree of bendability can be efficiently produced.

LaserSwiss combines fully-integrated laser cutting, along with machining operations which include turning, milling, tapping, drilling, thread whirling, grooving, sawing and chamfering. While some parts can be produced using solid stock, most components are tubular, often designed as single-use medical instruments or robotic surgical instruments. LaserSwiss is particularly well-suited to manufacturing a wide-range of medical device components. The level of feature complexity that LaserSwiss provides has revolutionized the manufacturing process, giving greater flexibility for engineers to design and manufacture parts that were not practical before.

Is LaserSwiss right for your project and will it be cost effective? Laser cutting is not only highly-accurate, it’s fast. In some operations, machining a part may take up to eight seconds, compared to one second for laser. However, machining operations are often necessary in part production. In LaserSwiss, having laser cutting and machining capabilities combined, means the optimal production process can be leveraged to make a component quickly, without moving from machine-to-machine. Additionally, integrated quality checks can be performed on the LaserSwiss – increasing efficiency without compromising the integrity, delicacy or precision required for surgical and medical components.

An examination of the ratio of laser cuts versus machining passes is an important part of the analysis. If there is a need for 50 laser cuts and only one machined cut, LaserSwiss might not be cost-effective. Finding the optimal fit of machining and laser features that makes a part right for LaserSwiss typically requires analysis by your manufacturing partner’s engineering team.

A customer may have a manufacturing process in mind that can be simplified. Having a collaborative engineering team with expertise in advanced laser processing, machining, as well as other manufacturing operations, helps customers identify which operations – or design modifications – can lower costs and increase manufacturability.

Design and functionality options, like assembly tabs on a device, or ramp features used for component removal, can often be efficiently produced while the part itself is manufactured. It’s also possible with LaserSwiss, and the help of a skilled engineering team, to simplify an assembly, or combine two parts into one, saving both time and money. LaserSwiss engineers may be able to identify process and cost-saving options that OEM’s might not have considered.

For parts with complex patterning, bendable components or intricate design elements, having a team of experts who can develop a laser process – or a machining process – that creates the desired pattern and flexibility using quick-turn prototyping, can be a crucial step before production. By developing the laser and machining processes separately, then combining both on the LaserSwiss, prototyping is efficient. Testing out design and manufacturability prior to production can streamline operations, control costs and optimize performance of medical components.