Laser processing brings you a new level of precision and efficiency – discover how our expertise can help your project.

AVNA ’ laser process engineers are recognized for their leadership in medical laser processing, inventing and integrating laser technologies to improve product manufacturing and final product performance. Our team will collaborate with you to develop a specialized welding, marking and surface treatment solutions for your application. We design and build custom laser systems in-house, with medical-grade quality and performance for your application.

Our total-view laser engineering takes manufacturing to the next level. As stamping, machining and assembly experts, we can go a step further – integrating medical laser processing at any step in the production process. From a single part to a complex assembly, AVNA is your single source for customer-driven innovation, in-depth engineering and technology and proven medical laser processing. Our team is ready to collaborate with you to solve complex challenges, optimize manufacturability, while considering form fit and function.

Lasers offer a variety of solutions to meet the increased demand for smaller, more complex medical device components. Medical laser processing, a closed-loop, repeatable and non-contact operation, maximizes compliance and precision. With flexible tooling, design for automation and precision robotic handling, laser processing optimizes performance, cost and quality.

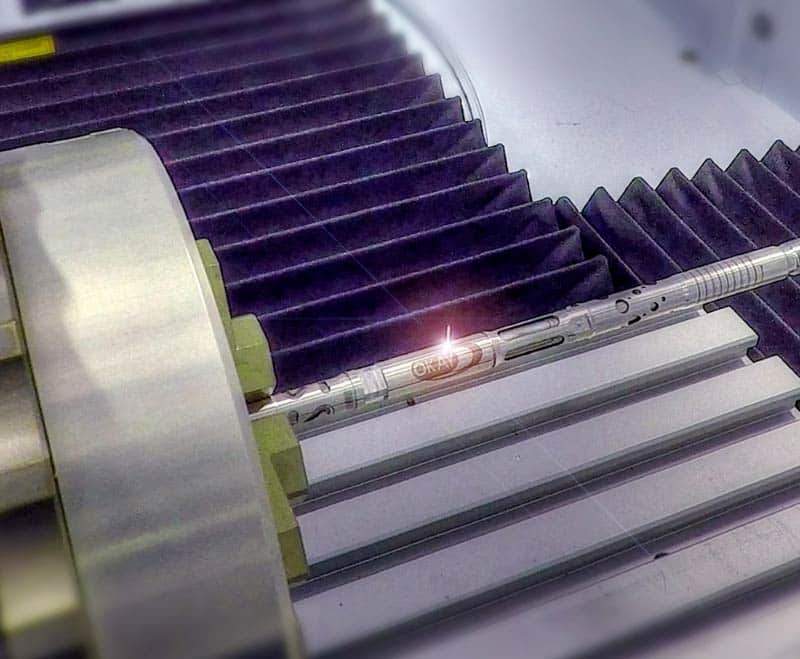

AVNA offers a wide variety of precision laser tube cutting and medical laser processing services. The depth and breadth of our machining and medical laser processing services allow us to provide the best solution – customizing technology and processes to maximize quality, performance and cost efficiency.

The depth and breadth of our machining and medical laser cutting services allow us to provide the best solution – customizing technology and processes to maximize quality, performance and cost efficiency of medical device components and assemblies. Our robust combination of advanced laser tube cutting equipment and technologies, including Accu-LaserSwiss, provides unmatched results for our customers.

Learn more about our laser tube cutting technologies and processes which deliver unmatched quality designed for precision.

An automated process that delivers the precise amount of weld energy needed to match your part’s geometry, our fully-automated medical laser welding process includes integrated tooling and vision systems.

Click HERE to learn more about our laser welding services and how our AVNA laser experts will collaborate with you to develop the best solution for your project.

From logos and graphics to part identification, our medical device laser marking helps you hit your mark. We design and build custom laser systems in-house, with medical-grade quality and performance for your application.

Whether for functionality or aesthetics, AVNA medical laser processing surface treatment services precisely comply with depth, pattern and dimensional specifications. Our non-contact lasers can polish or roughen any surface in preparation for the next manufacturing step, as well as eliminate the need for other finishing operations. The results are reliable, repeatable performance with advanced, validated process and quality controls. From polishing to anti-glare to patterning, our medical laser processing delivers the ideal surface finish for your project. Our laser processes are non-contact, eliminating debris, simplifying tooling and streamlining processes.

When accuracy and permanency are critical to your success, AVNA is ready with a solution to best fit your needs. Learn more HERE.

Lasers provide a variety of advantages – saving our customers’ time and money – while allowing the manufacture of quality and performance of parts that are always Part of Something Greater.

Schedule an appointment at our LaserWorks R&D laser prototyping lab, or request a quote for your project today.