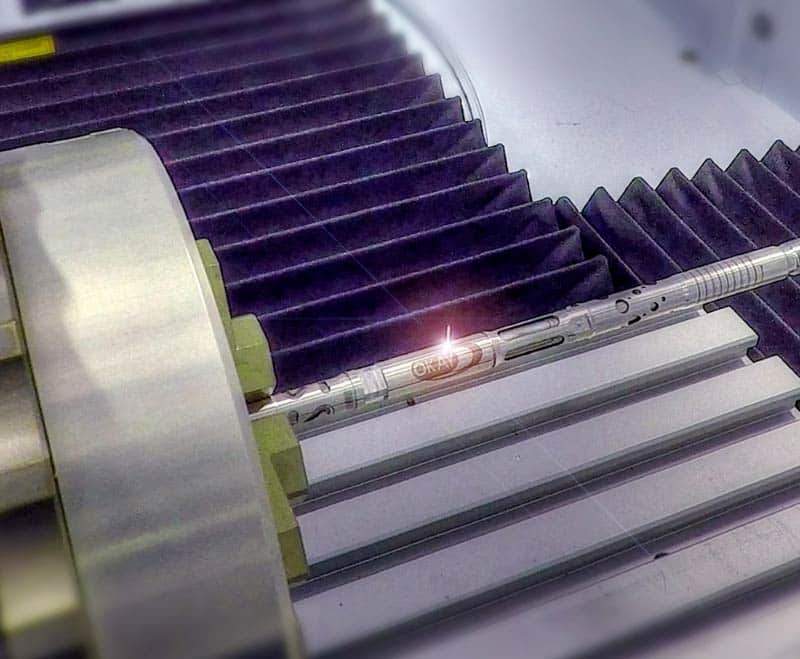

Laser marking produces smooth, dark, high-contract marks for device identification – from static visuals to serial numbers and 2D barcode symbology.

AVNA’s flexible medical device laser marking systems can easily handle a full range of shapes and geometries, from flat to spherical. Our laser marks are developed to withstand passivation and repeated cleaning.

From logos and graphics to part identification, AVNA’s Laser Process Engineers can help you hit your mark on visual and functional needs and are recognized for their leadership in medical laser processing, inventing and integrating laser technologies to improve product manufacturing and final product performance. Our team will collaborate with you to develop specialized marking, welding and laser cutting solutions for your application. We design and build custom laser systems in-house, with medical-grade quality and performance for your application.

AVNA offers a wide variety of precision medical device laser marking services. The depth and breadth of our machining and services allow us to provide the best solution – customizing technology and processes to maximize quality, performance and cost efficiency. Experience the AVNA difference with:

AVNA’s laser marking offers a variety of solutions to meet demand for complex medical device components, and our team will collaborate with you to develop specialized marking for your applications. Materials available include stainless steel (300 series, 17-4, 17-7), anodized aluminum, titanium, plastics, copper, brass. Laser marking solutions offered by AVNA include:

Medical Device Laser Marking Done Right. Talk to an AVNA engineer today.

Our team is ready to collaborate with you to solve complex challenges, optimize manufacturability, while considering form fit and function. The range of our machining and medical laser marking services allow us to provide the best solution – customizing technology and processes to maximize quality, performance and cost efficiency of medical device components and assemblies such as cannulas, needle assemblies, obturator & trocar, debrides, burr-blades, continuous or interrupted spiral design, articulated joints, puzzle-lock pattern, pull ring assemblies, link and spring welded assemblies, catheters and suture anchors.

Our quality systems, product quality planning and advanced measurement techniques are recognized by the world’s largest medical device companies. Contact our team today to discuss your laser marking, laser cutting and/or laser welding needs. Contact us or schedule an appointment in our NexTech Labs and discover how our customer-focused collaboration will improve outcomes on your next project.