AVNA sets the standard for precision, speed, and cleanliness, while meeting the strictest tolerances.

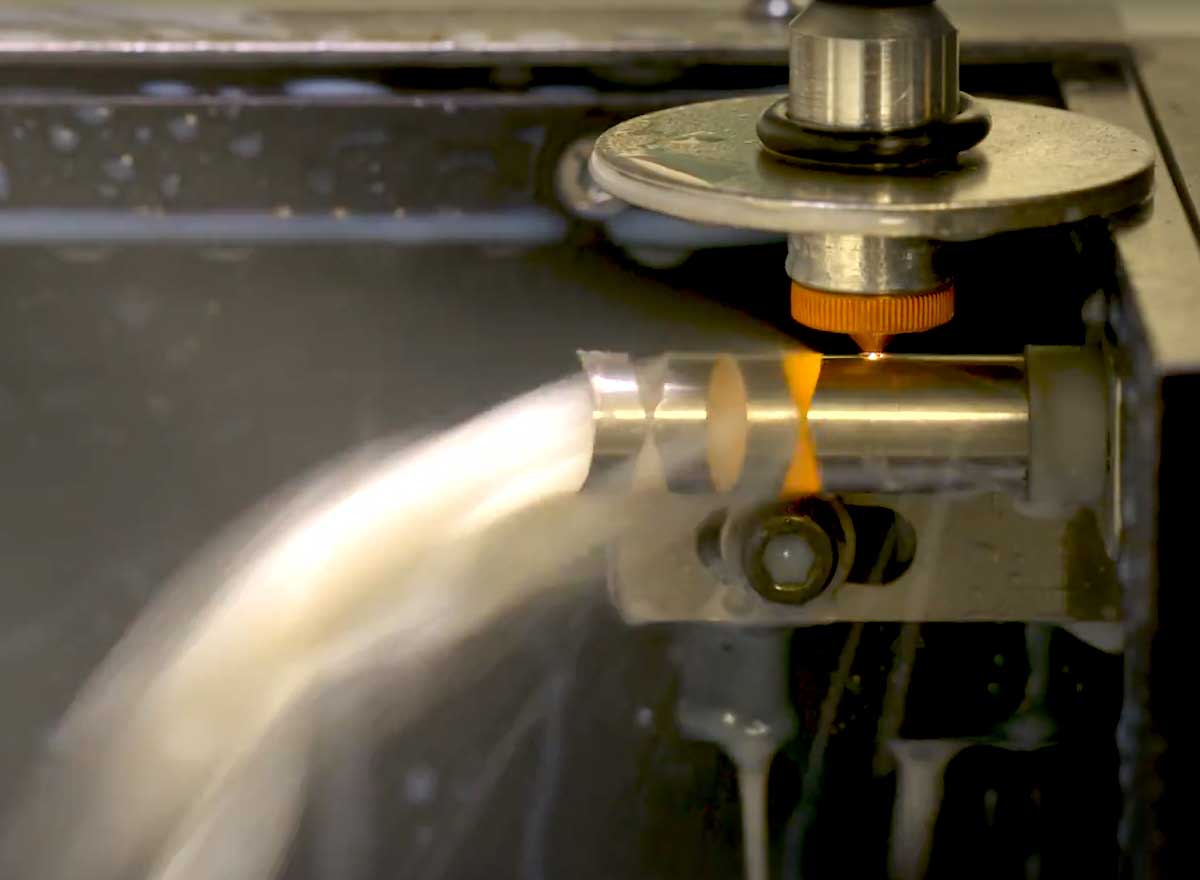

Our laser tube cutting is customized to your unique application, delivering the quality and compliance needed for precision medical applications. Our specialized processes and team of Laser Process Engineers optimize our four, five, and seven-axis equipment to meet the statistical quality requirements and maintain tight tolerances medical device OEMs demand and rely on.

OKAY’s Laser Process Engineers will work with you to create your unique components and assemblies, developing specialized processes and even custom-building laser equipment in-house. Our services are designed to ensure your project is streamlined and optimized to deliver the best possible results.

With laser cuts as small as .0015-inches (.0381mm) wide, our process provides precision advantages – producing sharp, accurate features allowing more intricate designs, with the ability to implement sensors for locating/clocking parts, as well as feeders and robots for automatic load/unload (for specific applications).

OKAY’s laser tube cutting offers a superior combination of equipment, including Class 1 custom designed 4-5 Axis laser cutters (manual and fully automated options), technology, software and engineering expertise. Our extremely narrow laser cut capabilities reduce process heat and virtually eliminate the discoloration and warping that can occur with other technologies. Additionally, laser tube cutting allows material removal with zero tool wear – all the work done by the laser – which helps lower production costs.

Talk to an AVNA Engineer Today

Our robust combination of advanced laser tube cutting equipment and technologies, including Accu-LaserSwiss, provide unmatched results for our customers. Our team will consider the ratio of machining to laser tube cutting services and customize our processes and technologies to your specific project needs.

The experienced AVNA laser team can create part geometries that replace traditionally milled or wire EDM manufactured parts at a fraction of the cost, can process shaped and formed tubing, as well as hand loaded parts (manual or fully automated), and tilted cuts to create beveled edges and sharp teeth. We are ready to maximize our services for your project requirements:

Available material types include:

The depth and breadth of our machining and medical laser cutting services allow us to provide the best solution – customizing technology and processes to maximize quality, performance and cost efficiency of medical device components and assemblies such as cannulas, needle assemblies, obturator & trocar, debrides, burr-blades, continuous or interrupted spiral design, articulated joints, puzzle-lock pattern, pull ring assemblies, link and spring welded assemblies, catheters and suture anchors.

AVNA ’ laser technology will exceed your expectations, with customized processes, expert capabilities and specialized Laser Process Engineers ready to assist to make your component Part of Something Greater. Bring us your ideas, concepts, and toughest challenges and we’ll deliver innovative solutions that exceed your expectations.

Contact us or schedule an appointment in our NexTech Labs and discover how our customer-focused collaboration will improve outcomes on your next project.