Making Headlines

When you make outstanding products, you make news.

The medical device industry demands efficiency and precision. At the heart of many ground-breaking traditional, minimally invasive, and robotic assisted surgical devices lie innovative metal tube components and assemblies that require equally-matching manufacturing capabilities. AVNA, a leading medical manufacturing partner, offers advanced laser tube cutting services with vertically integrated secondary processes and plastic overmolded capabilities that are helping medical device manufacturers transform healthcare around the globe.

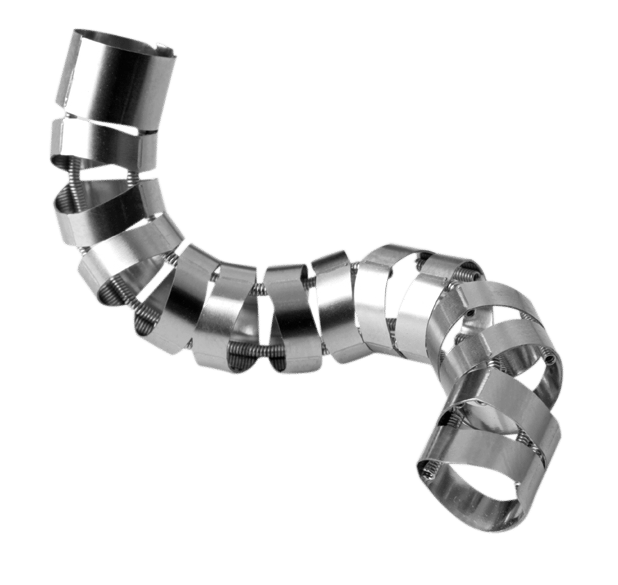

Traditional, minimally invasive, and robotic assisted surgical devices require intricate metal cut tubes, cannulas, and shafts to meet the stringent performance requirements of their innovative devices. From tissue manipulation, electrosurgical procedures, monitoring, visualization, and guidance/navigation, the applications are vast.

AVNA specializes in cutting a wide range of tube types, including shaped, formed, and closed-end configurations, from materials like stainless steel (300 series, 17-4, 17-7), titanium, nitinol, and aluminum. These materials are carefully selected based on the specific requirements of each application.

Key performance characteristics for flexible type components such as: pushability, torqueability, bendability, kinking, and trackability are paramount in medical devices. These properties are directly influenced by the precision and consistency of the tube cutting process. AVNA offers collaborative early-stage design for manufacturability support to ensure speed to market and optimal performance of their product designs.

AVNA’s state-of-the-art laser cutting equipment is at the forefront of the industry. Our laser cutters, include 4-axis and 5-axis models with a tiltable-laser head (+90◦/-20◦ for cutting 3D shapes), enable exceptional flexibility and precision. The use of fiber and pulsed lasers among advanced technologies like Motorized Focus Heads and Position Synchronized Output (PSO) ensures optimal results customized for each application.

To further streamline production, AVNA offers custom fully automated options, capable of handling large volumes of components and lights out operation. Our ongoing commitment to innovation is evident in the development of this new proprietary equipment, designed to deliver even greater efficiency and precision.

Hand selecting the latest advanced technology in the industry, AVNA’s laser process engineers have customized our own set of laser tube cutters to improve cut quality, increase process speeds, and minimize/eliminate secondary deburring. The result is improved throughput and improved overall process quality controls.

The latest motion controllers feature an LCI module which enables the use of PSO for equal spacing of laser pulses in real-time. Allowing parameter changes on the fly, these controllers facilitate increases in process speeds and improve cut quality around low-speed corners to minimize or eliminate the reliance of post-process deburring/cleaning.

Motorized focus heads allow for changing focus on the fly to improve cut quality during off axis cutting. Moreover, this eliminates manual adjustments and potential errors. A cover lens monitor improves overall process control by continuously monitoring the process and automatically stopping the process if a contaminated cover lens is detected. This decreases potential rework and scrap.

A custom cutter box and guide bushing design is optimized to facilitate consistent repeatable machine setups, and decreased machine downtime. Programmable Dual Assist Gas allows the ability to control gas type and pressure output in process on the fly for improved cut quality.

Gas and coolant pressure monitoring systems ensure operation within the allowable ranges and automatically stops the machine if a deviation from the set point is detected.

The team at AVNA co-developed our Accu-LaserSwiss processes to deliver efficiency and lower costs on complex components that require both machined and through laser cut features, helping customers save time and cost. This process is a fusion of CNC Swiss lathe technology with laser capabilities, resulting in the groundbreaking LaserSwiss process. This revolutionary approach dramatically reduces cycle times by combining the strengths of both technologies into one package.

AVNA offers a comprehensive range of laser cutting options to meet the most demanding design specifications:

AVNA’s vertically integrated services complement its precision laser tube cutting to provide complete manufacturing solutions that optimize speed to market, performance, and cost savings of every part and assembly that leave its facility:

By offering a comprehensive suite of services, AVNA provides a single-source solution for medical device manufacturers, simplifying the supply chain and accelerating time-to-market.

AVNA’s commitment to quality and precision, coupled with their advanced laser technologies, makes them the ideal partner for medical device OEMs seeking to develop cutting-edge products. By leveraging AVNA’s expertise, we can collaborate with your team to overcome manufacturing challenges, reduce costs, and bring innovative medical devices to market faster.

Contact AVNA today to discuss your next project and explore how their advanced laser tube cutting services and the AVNA Advantage can elevate your product.